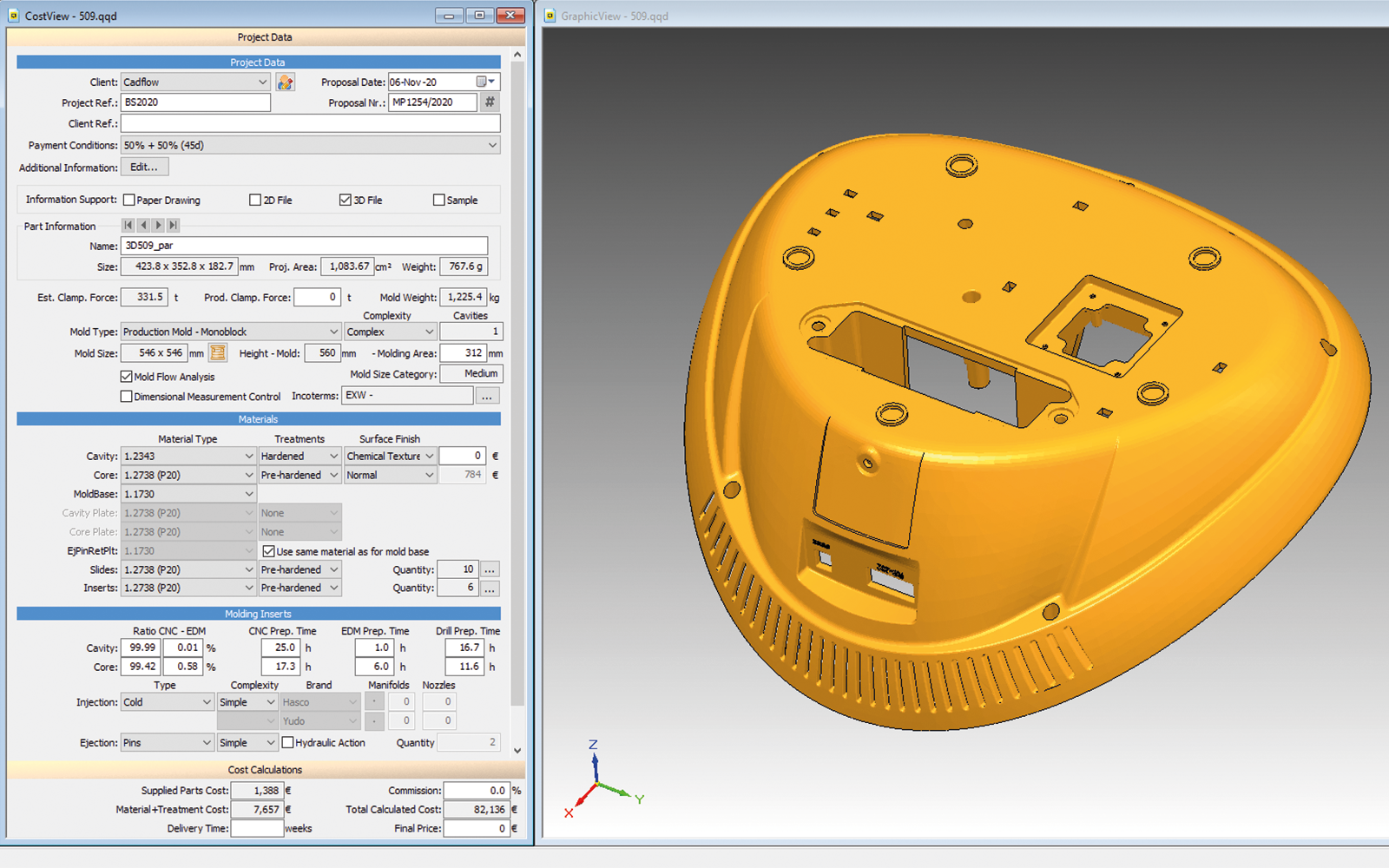

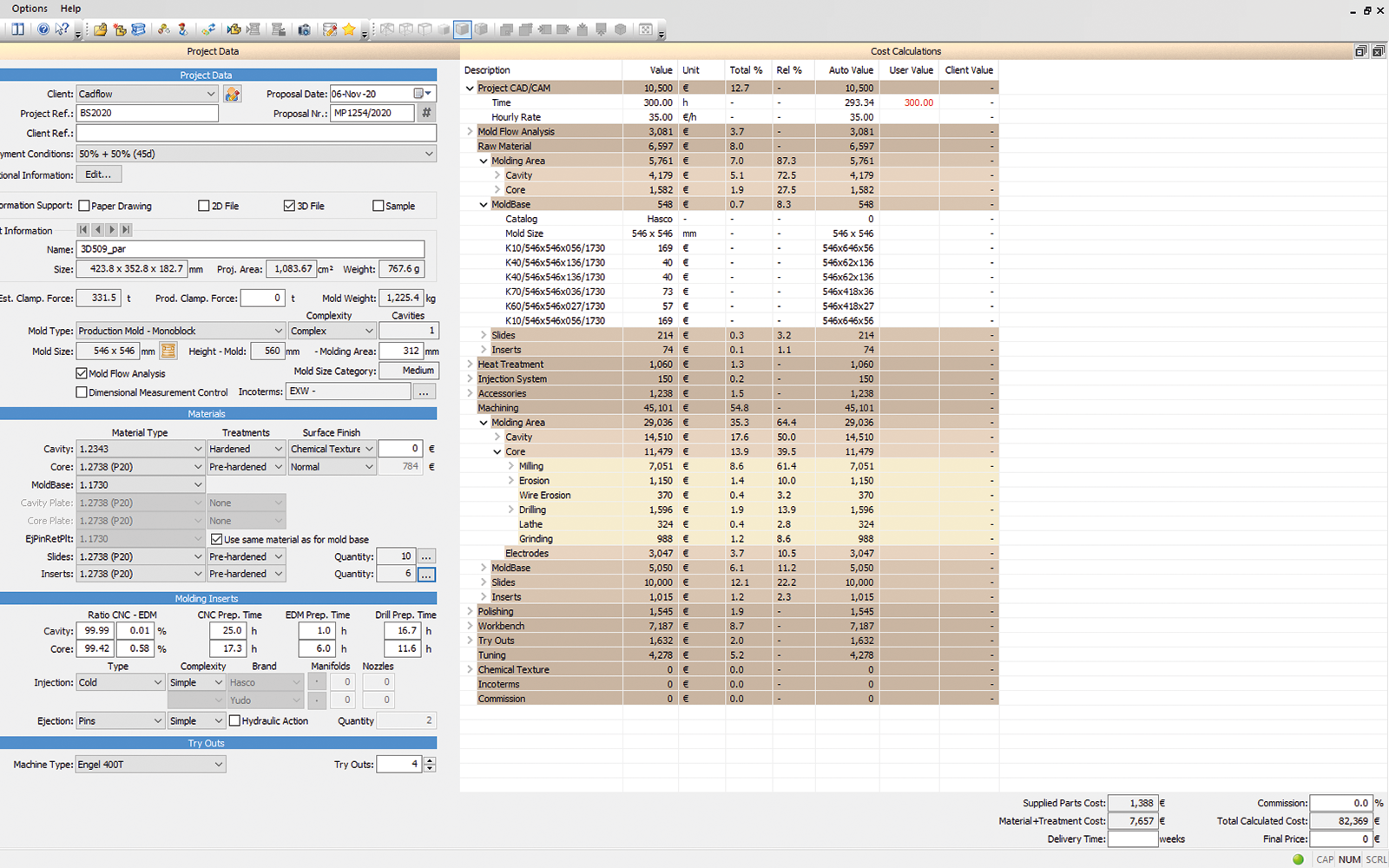

QUICKQUOTE is a software that allows you to create quick and accurate estimates for the molds manufacture.

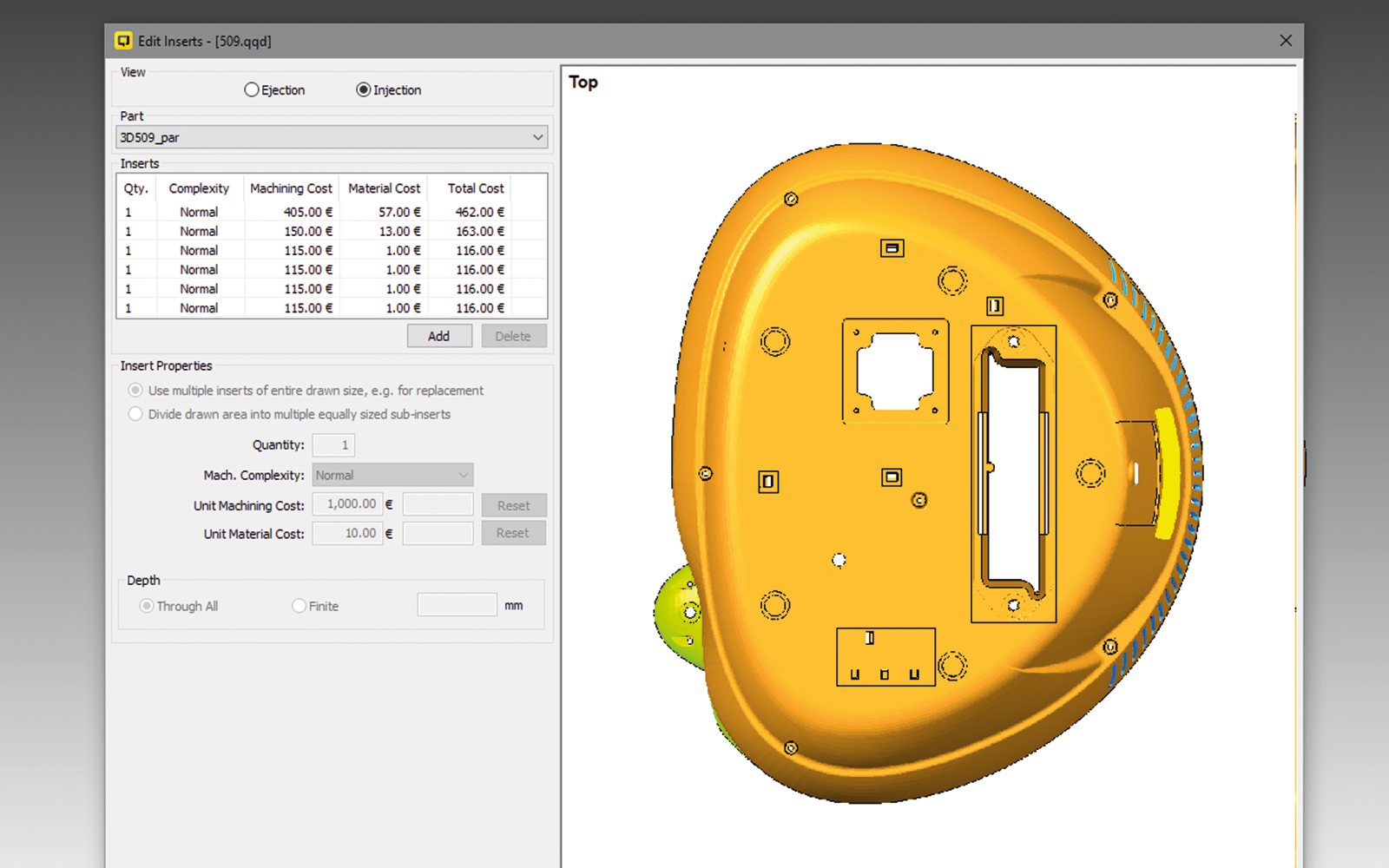

Categorization and detailed report of expenses.

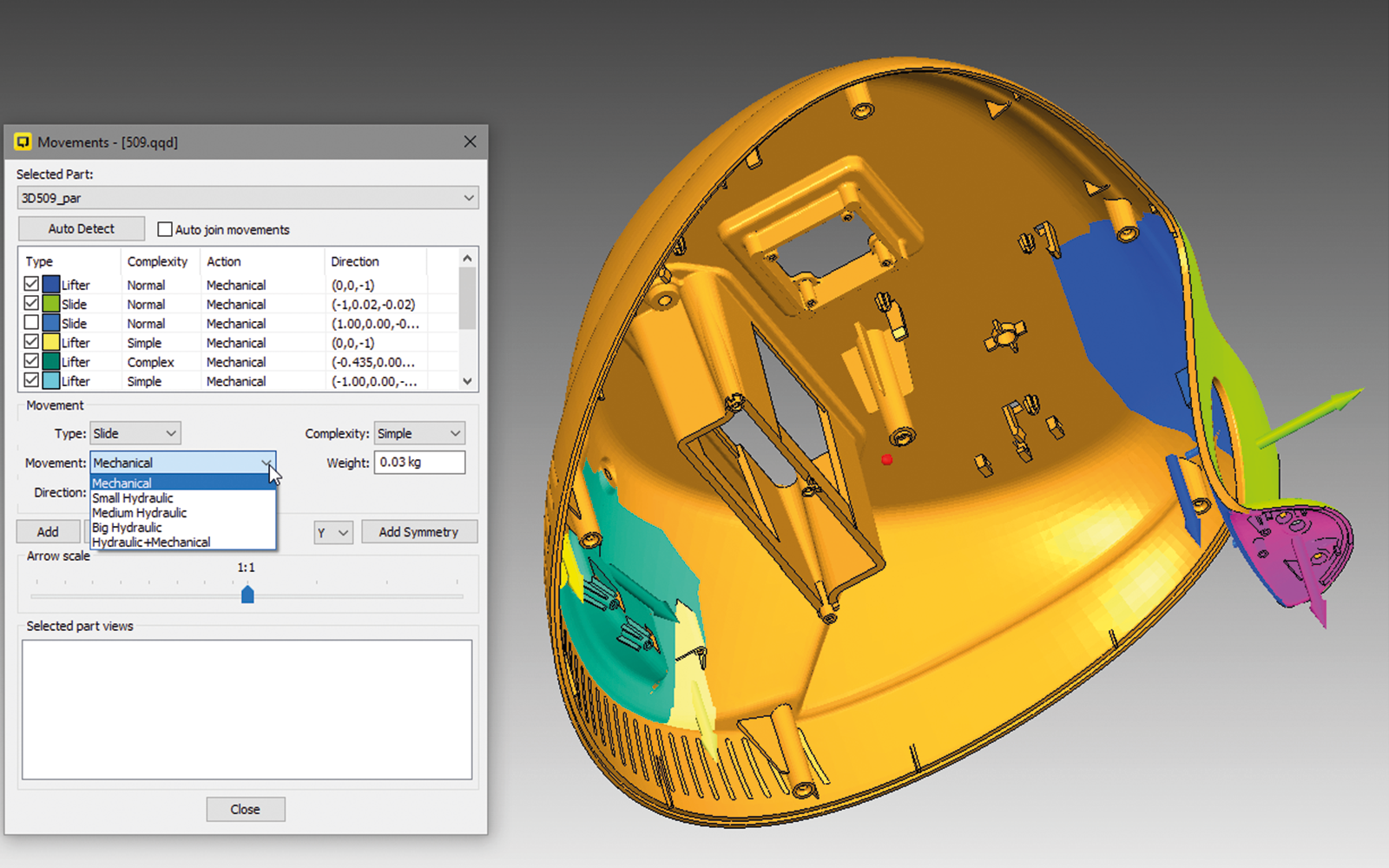

Automatic detection of negative areas and definition of slides and lifters.

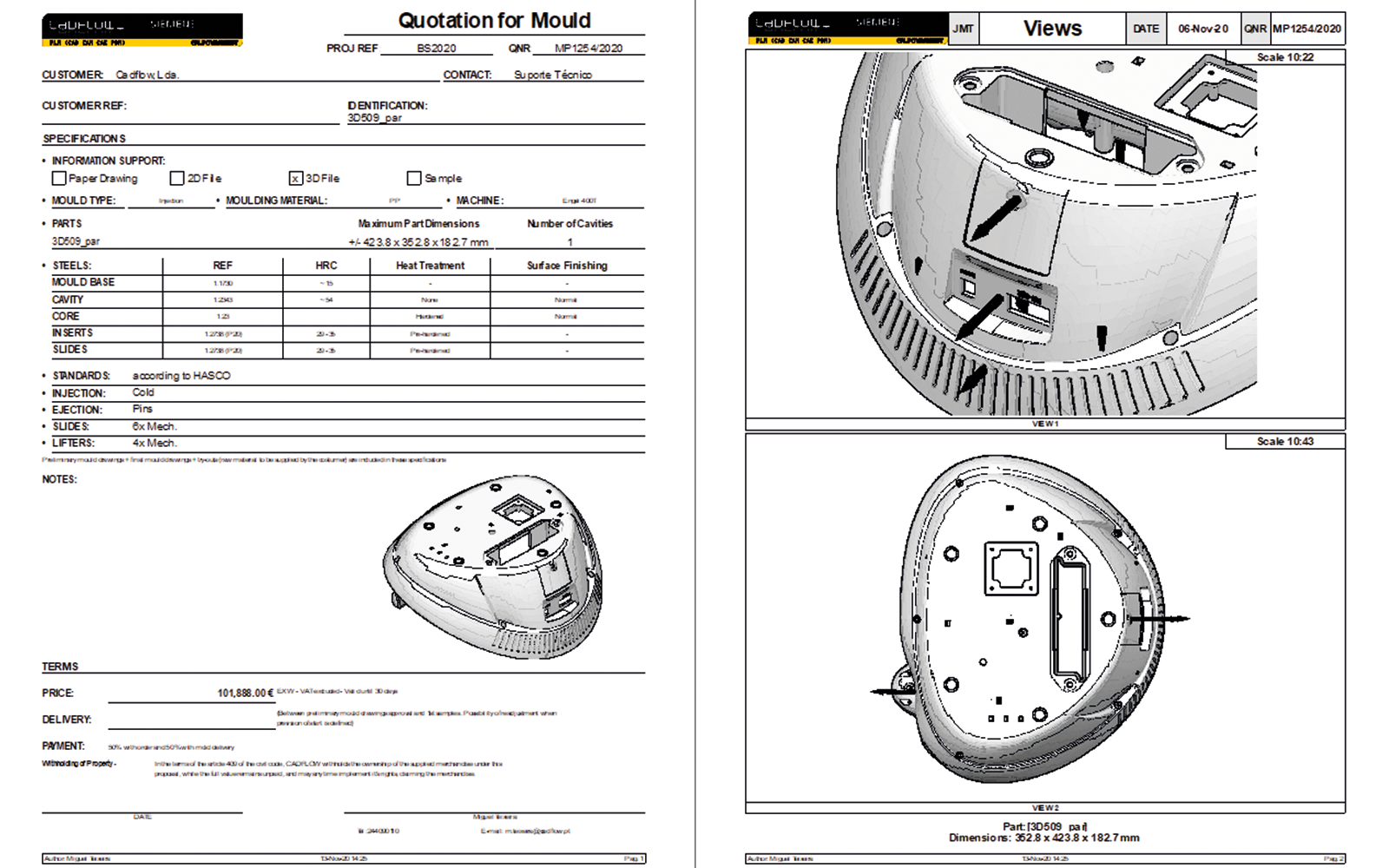

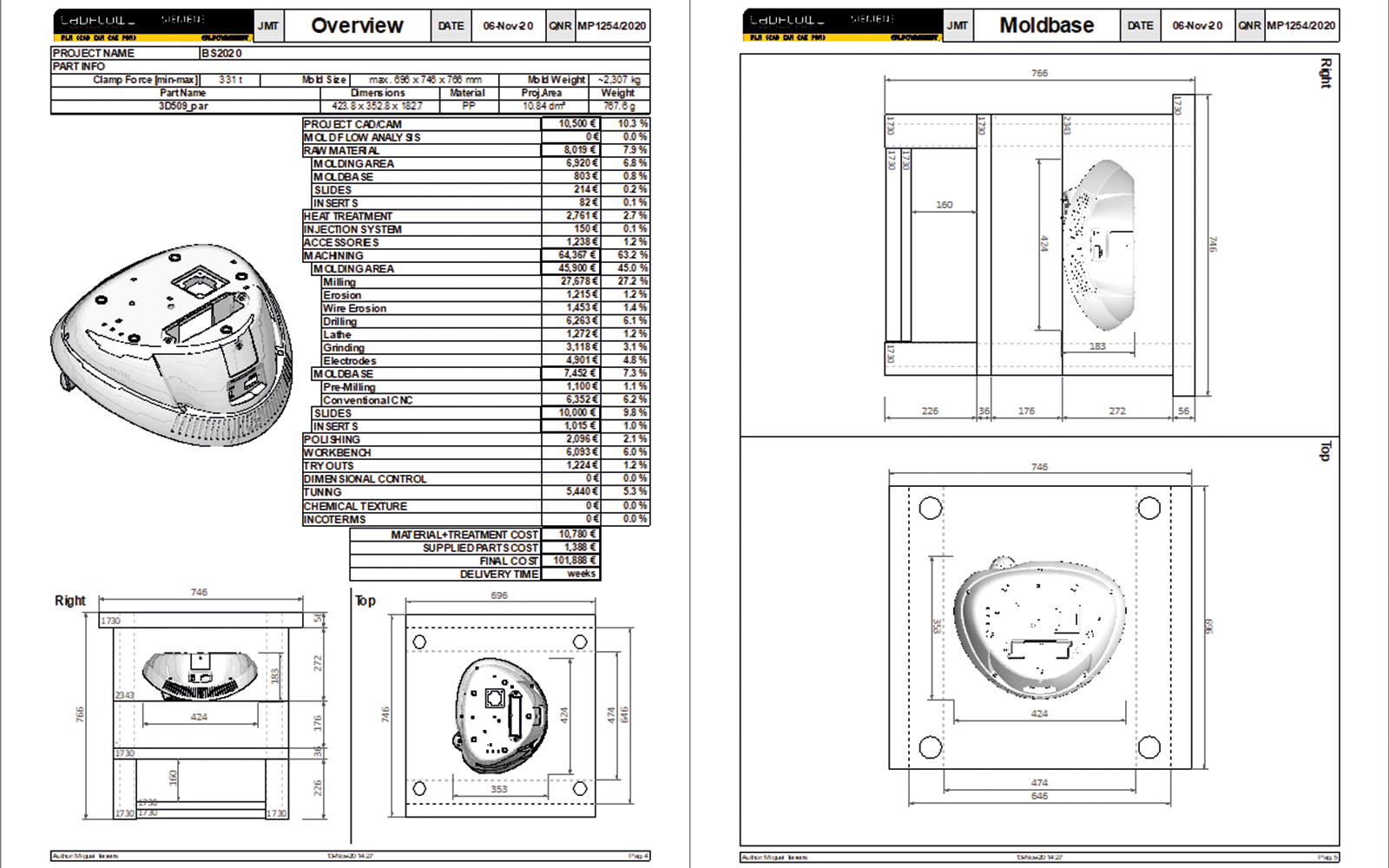

Automatic creation of commercial documentation.

Easy and quick definition of direct moldable areas and sliding elements.

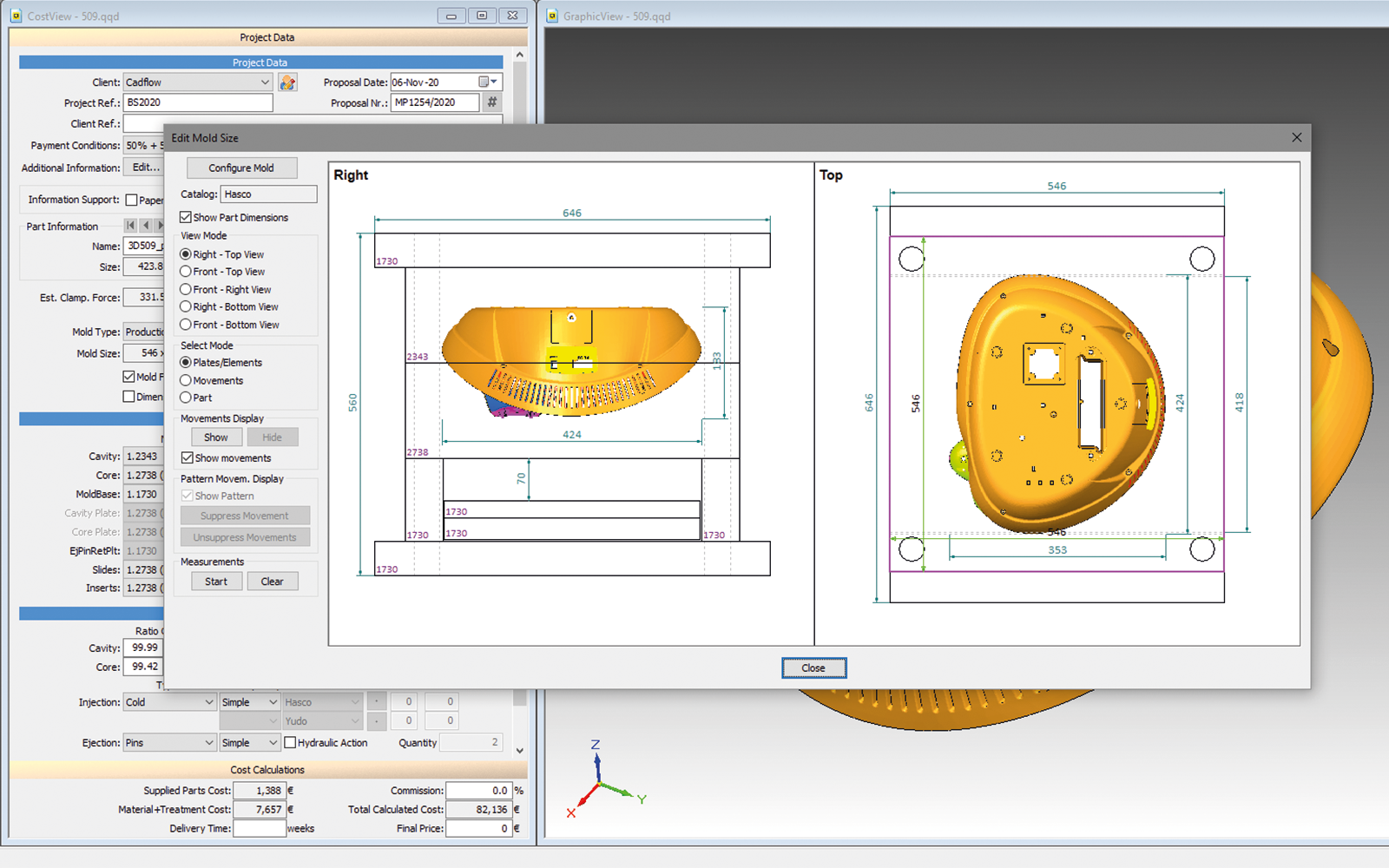

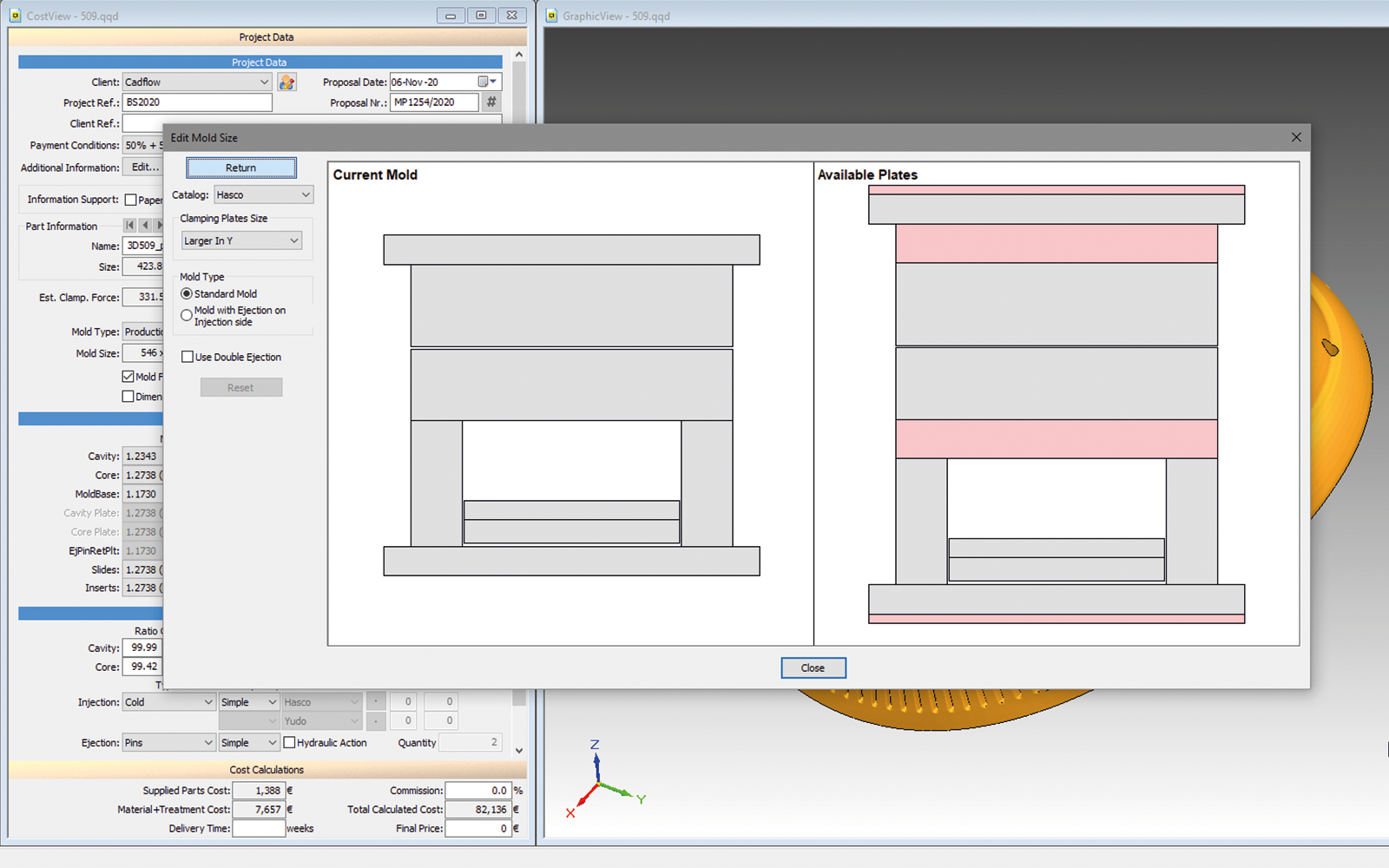

Dynamic adjustment of mold plate dimensions and its components.

Automatic detection of ribs and other specific details on the part.

Geometry Easy to Import

SPEED IMPORT

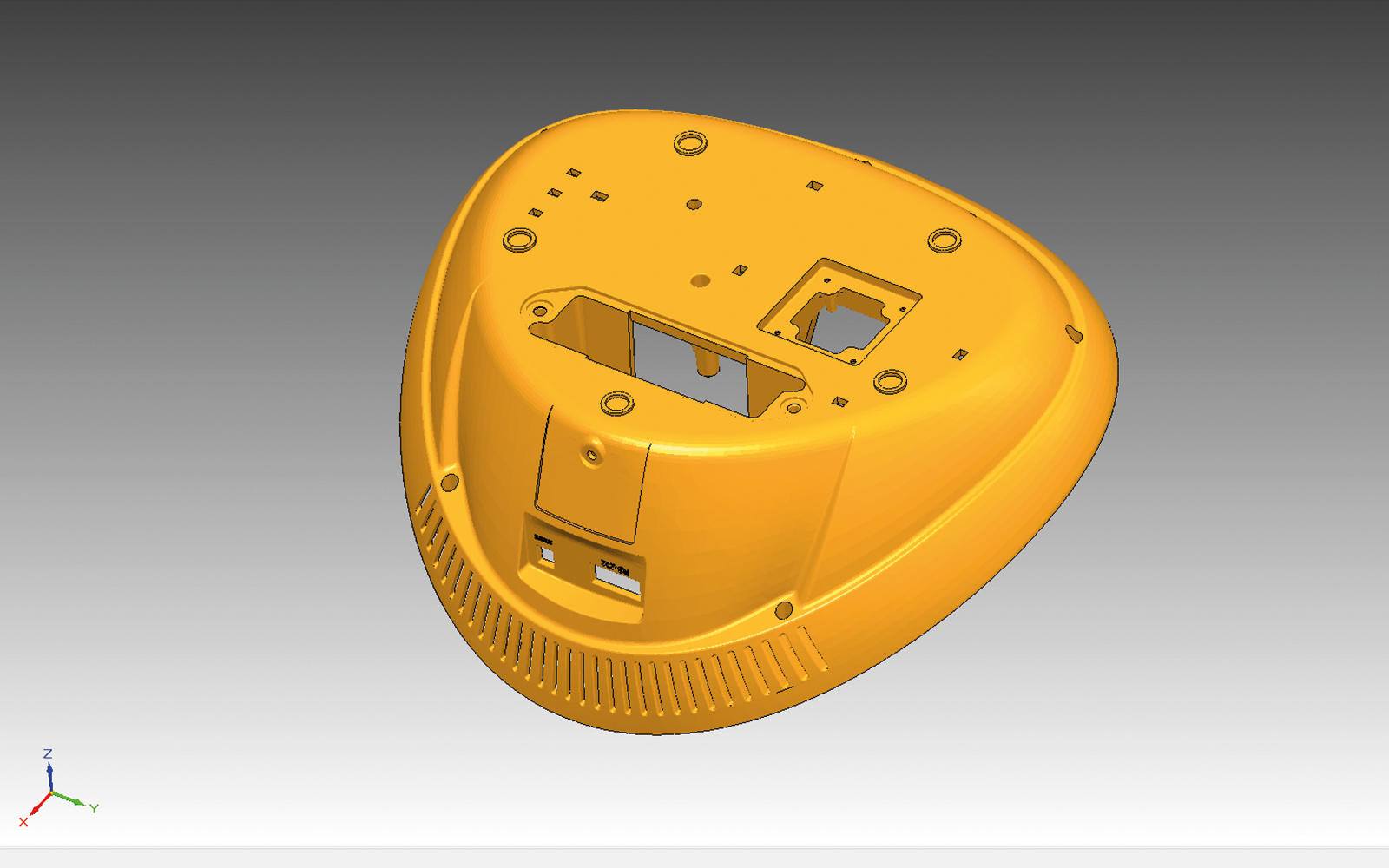

QUICKQUOTE allows you to import the part geometry in STL format. This lightweight format is simple, accurate and universally used, which assures that the model received from the potential costumer is easily and quickly introduced into the quotation system, allowing the operations to be fast and dynamic.

Nowadays, requests for mold quotations are increasingly being created in a massive way: with a single click, a customer can request for a quotation from hundreds of potential suppliers.

There is a need to quickly deliver an accurate and reliable proposal. With QUICKQUOTE, you just need to select the 3D model of the part and set the initial parameters, that a value is instantly calculated based on the part’s geometry and user preferences. Any change on any parameter causes an immediate update of the final value, allowing quick analysis of different approaches to mold design.

Easy Quotes

EASY TO COSTUMIZE

To support companies of different sizes, QUICKQUOTE is installed with a database with average costs and hour rates, that reflect the general reality of the mold industry. His allows you to start quoting immediately, without complex customizations.

Also, with QUICKQUOTE, forms and reports templates are installed, that can be adapted to your needs, so you can automate the documentation output, with minimum effort due to the common technologies used.

Automatic Documentation

PRECISION RESULTS

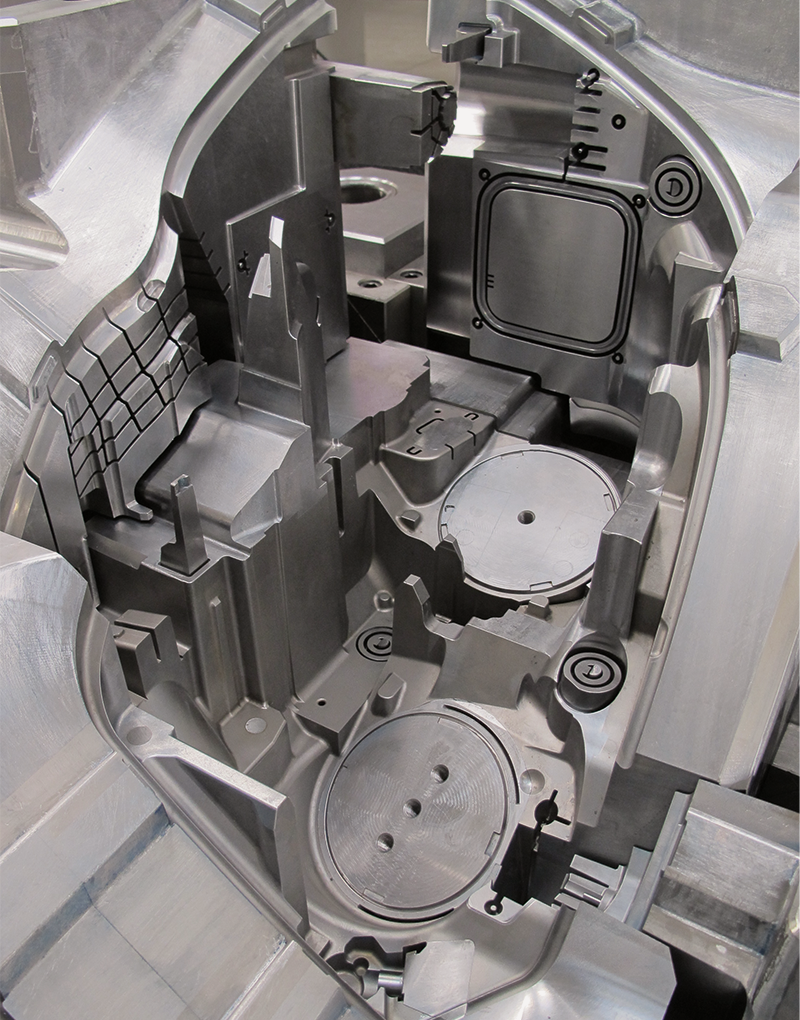

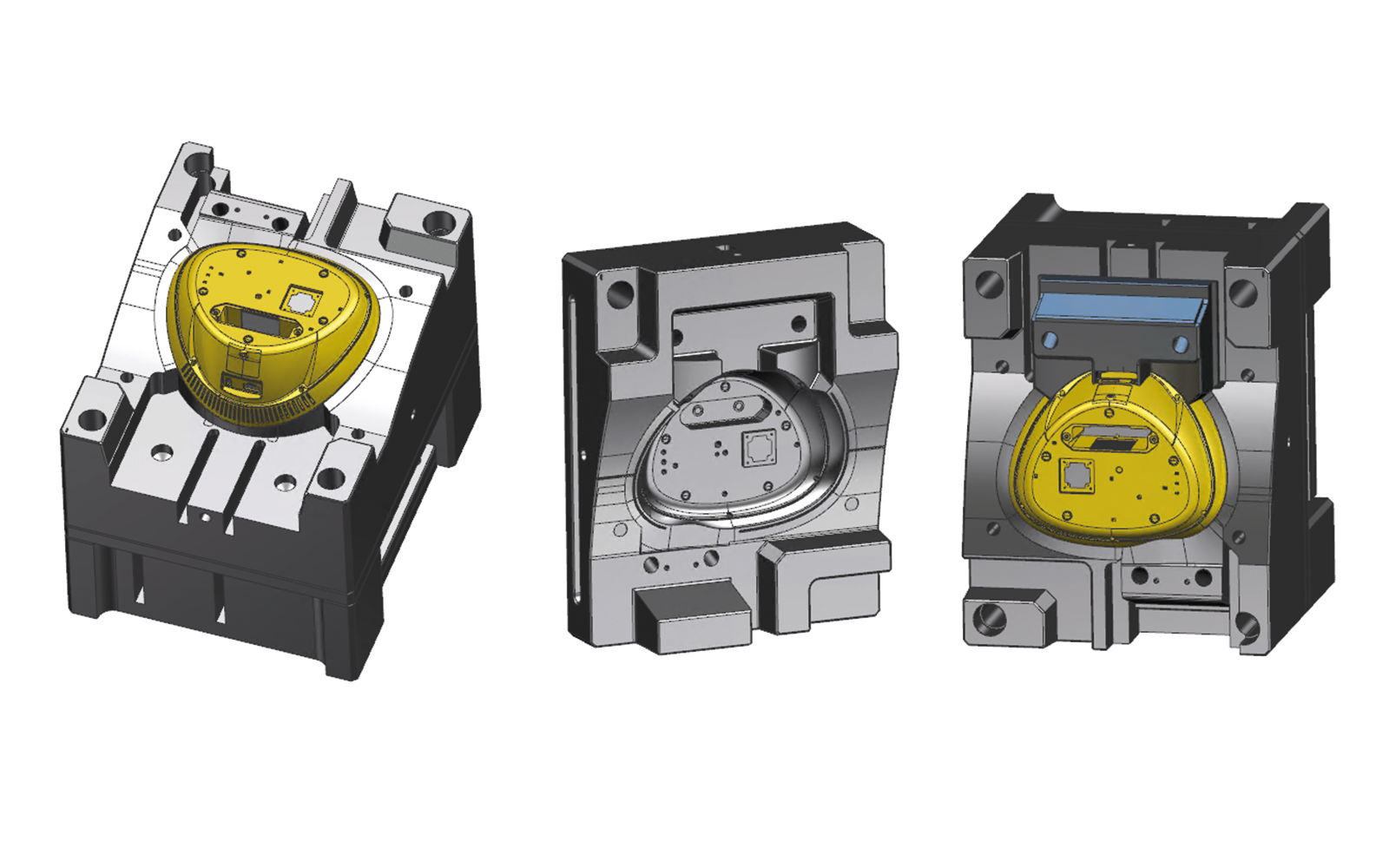

QUICKQUOTE automatically produces the preliminary drawings of the mold structure and representation schemes of slides and lifters. This allows the users to have a better perception of the work to be done and increases their level of confidence.

The slide components of the mold are the details that most influence the final cost and are also the most difficult mold components to predict empirically. The current solutions on the market use extensively abstract parameters, and the user has to introduce an abstract value without knowing its impact on the final cost of the mold. This lack of transparency causes nondeterministic results and does not adequately reflect the specific industrial realities in which the project is developed.

The use of 3D models, associated with the automatic detection of movements and other important details of the mold, while considering the part geometry, reflects an adequate description of the industrial reality in which the project will be developed.

Automatic Documentation

PRECISION RESULTS

QUICKQUOTE automatically produces the preliminary drawings of the mold structure and representation schemes of slides and lifters. This allows the users to have a better perception of the work to be done and increases their level of confidence.

The slide components of the mold are the details that most influence the final cost and are also the most difficult mold components to predict empirically. The current solutions on the market use extensively abstract parameters, and the user has to introduce an abstract value without knowing its impact on the final cost of the mold. This lack of transparency causes nondeterministic results and does not adequately reflect the specific industrial realities in which the project is developed.

The use of 3D models, associated with the automatic detection of movements and other important details of the mold, while considering the part geometry, reflects an adequate description of the industrial reality in which the project will be developed.

Technical Support

TUTORIALS

QuickQuote Worldwide

PARTNERS

Europe

ATS Spain

Easysteel

Enterprise

Kaizen PLM

Ireland and UK

https://www.kaizenplm.ie/

PAWFORM

Poland

https://pawform.pl/

Boğaziçi Yazılım

North America

CGS North America

(CAM TOOL)

USA and Canada

https://www.camtool.com/

South America

BUSMAN

DPR ENGENHARIA

Africa

ULTIMATE PARTNER

South Africa

https://ultimatepartner.co.za/

Asia

3D Engineering

AMFAH International

Oceania

CAD Central

New Zealand

https://www.cadcentral.co.nz/

Send us your message

CONTACT US

Address

Complexo Industrial Vangest – Building 2

Rua de Leiria, 210

2430-091 Marinha Grande

Portugal

Phone number

(+351) 244 090 110

Chamada para rede fixa nacional.

quickquote@cadflow.pt